In the fields of manufacturing, automotive industry, metal processing, etc., precise detection of coating thickness is of vital importance. This mini coating thickness measuring instrument, with its professional performance, wide applicability and convenient operation, has become a reliable assistant for professionals in the industry.

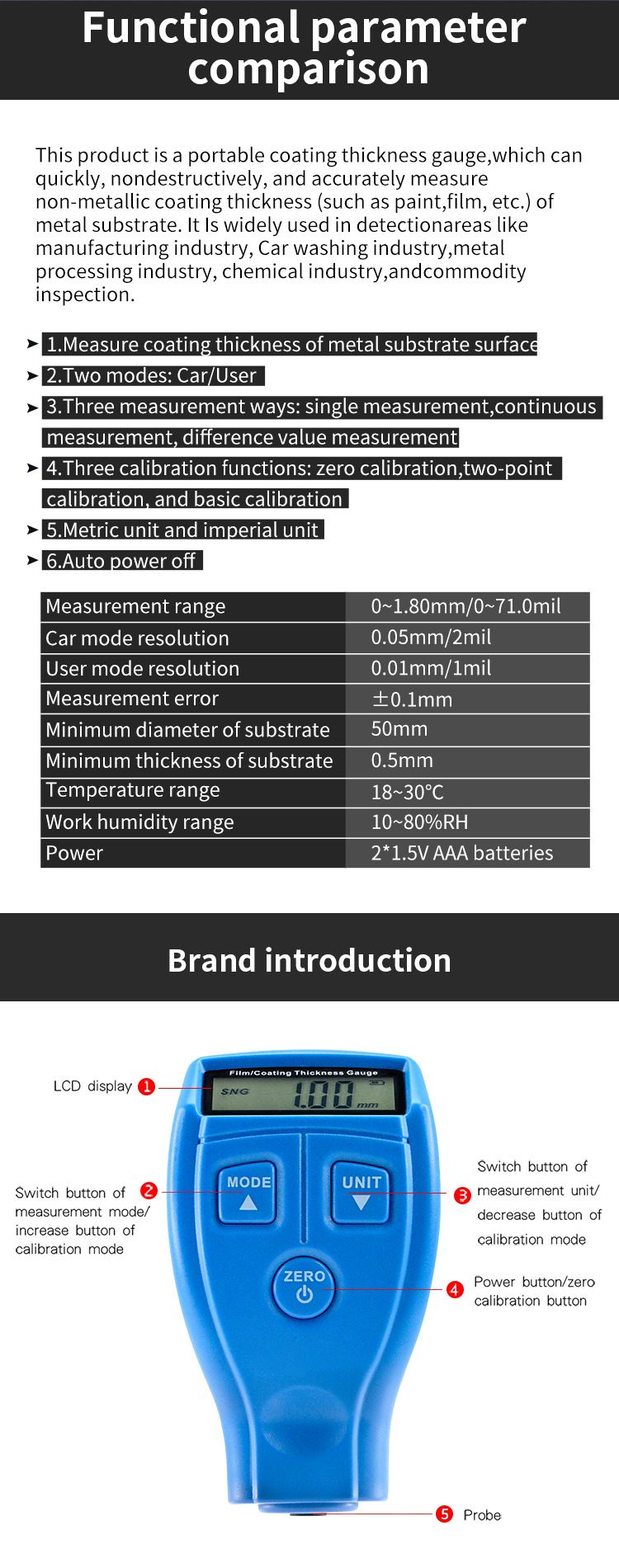

It is specifically designed for measuring the thickness of non-metallic coatings on metal substrates, such as paint and films. The measurement range covers 0 to 1.8mm, with an error of only ±0.1mm, and its accuracy far exceeds the industry average level. Whether it is for quality control of manufacturing products, paint surface inspection in the automotive cleaning industry, coating monitoring in metal processing and chemical industries, or in the field of commodity inspection, it can perform outstandingly.

In the fields of car beauty treatment, industrial painting, and metal processing, the control of coating thickness directly affects quality and durability. Too often, we can only judge whether the coating meets the standards based on experience, only to regret it later when problems such as peeling or corrosion occur. Now, this Film/Coating Thickness Gauge (film / coating thickness gauge) has broken through the bottleneck with professional accuracy and diverse functions, becoming the "sharp eyes" for coating thickness detection.

In the fields of car beauty treatment, industrial painting, and metal processing, the control of coating thickness directly affects quality and durability. Too often, we can only judge whether the coating meets the standards based on experience, only to regret it later when problems such as peeling or corrosion occur. Now, this Film/Coating Thickness Gauge (film / coating thickness gauge) has broken through the bottleneck with professional accuracy and diverse functions, becoming the "sharp eyes" for coating thickness detection.

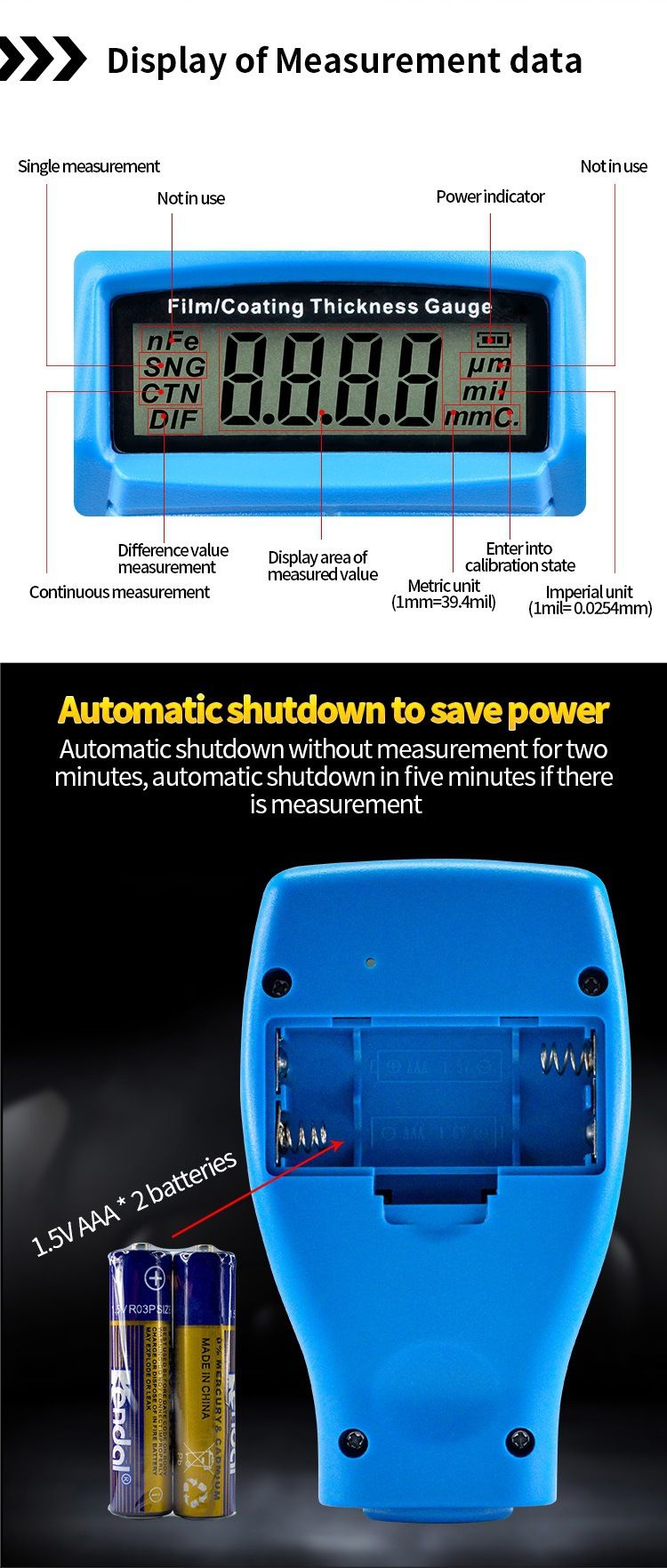

It deeply understands the industry's pain points and sets up a Car/User dual mode. Whether it is the precise detection of car paint surfaces or the user-defined measurement requirements in industrial scenarios, it can precisely match. The measurement modes are also rich. A single measurement can quickly obtain single-point data, continuous measurement can dynamically track changes in coating thickness, and differential measurement helps with comparative analysis, covering all aspects of detection logic from single points to trends and differences, providing comprehensive satisfaction for detection logic.

The calibration system is also professional, with zero-point calibration, two-point calibration, and basic calibration as triple guarantees, ensuring that each measurement is anchored on a precise benchmark, making the data reliable enough to directly serve as the basis for quality assessment. The operation is also highly user-friendly, with the "MODE" key for mode switching, the "UNIT" key for freely switching units, and the "ZERO" key for one-click calibration upon startup. With just a few simple steps, you can start professional-level detection.

From the paint quality inspection in 4S stores of cars, to the coating thickness control in metal processing factories, and to the coating construction acceptance in the decoration industry, this thickness gauge can become the core tool for quality control. It is not just an instrument, but also your "precision partner" in the field of coatings, making the thickness of each layer of coating clearly visible, upgrading quality control from "by feeling" to "by data", and helping each project achieve precise thickness, creating outstanding results that are durable and exquisite in appearance.